Wooden box production process

What is the use of mold in the wooden box?

2019-11-22

The use and characteristics of camphor

2019-11-22First, the wooden box will be processed into a thick and thin sheet, the surface should be smooth, and then the sawing board is spliced, and the general white latex is used for splicing. Then fixed, after a day it will do it. Wine wooden box packaging

Secondly, the treated wood board should be polished, and then put on the putty. After a day of polishing, if it is uneven and then polished, it must be smooth because it depends on the smoothness and smoothness of the paint. Finally, the primer is applied. After a day of polishing, you can use water sandpaper, starting from 600, and then painting and then grinding more than 600, until the hand feels smooth. Finally brush the topcoat, thin and even. It will be completed in a week. Wine wooden box packaging

Finally, you can draw beautiful patterns on the wooden box. If you have special requirements, you should also specialize in pattern making, soak the prepared pattern in water for a few seconds, take it out and stick it directly on the wooden box, then use the scraper to hang the water inside, and leave it. After less than 10 hours, gently peel off the upper plastic film and cover it with a top coat.

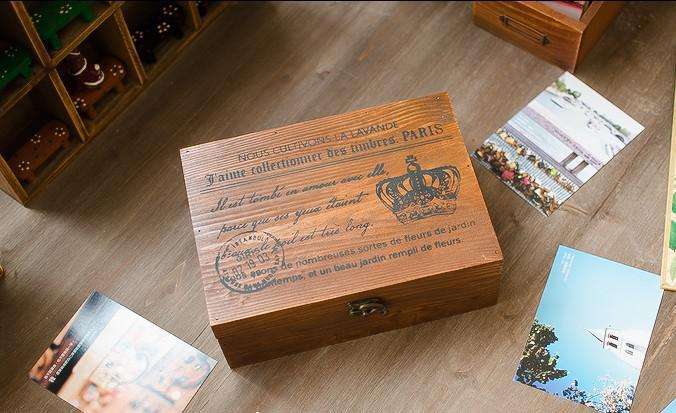

Laser engraving pattern. Laser engraving uses the laser head on the laser engraving machine to punch out the pattern on the surface of the wooden box. It is easier to understand than hot stamping, but the production cost is relatively high.

Screen printing process. The screen printing process is the simplest way to print in wooden box packaging. First of all, we must first print the screen printing screen, and after the drying version, it is the coloring process. Because many customers require different colors for the pattern, they should be color according to the color required by customers. After adjusting the color, put the screen plate on the box that needs to be printed, and then print the pattern with the ink. Red wine wooden box packaging

Hot stamping. Hot stamping, also known as branding, requires a hot stamping machine before hot stamping. To engrave the pattern on the copper plate, after the engraving, take the copper plate and screw it on the hot stamping machine, set the grinding tool and start heating. Pay attention to the temperature adjustment during the heating process. The temperature is too high and the hot stamping is black. When the temperature is too low, the hot stamping effect is not so obvious. After adjusting the proper temperature, it can be stamped on the wooden box. Wine wooden box packaging.